Typical Application

- Top Page

- Business Operations and Products

- Typical Application

Laser Welding & Cutting

Remote Laser Combined Processing

This is a system that can execute welding, cutting and other processing in continuation with a single laser head by changing the process condition setting for the laser oscillator and the robot, whereby the takt time can be shortened.

This is a system that can execute welding, cutting and other processing in continuation with a single laser head by changing the process condition setting for the laser oscillator and the robot, whereby the takt time can be shortened.

The picture shows a sample being cut, drilled and welded sequentially without interruption.

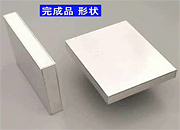

High-speed Remote Sealing

Remote laser processing with long focal length optical system allows highly flexible processing by attaching a laser head to a robot arm.

Remote laser processing with long focal length optical system allows highly flexible processing by attaching a laser head to a robot arm.

The picture shows a sample of aluminum box sealed with remote laser welding. Remote laser processing is applicable to processing in narrow area.

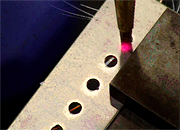

Robotic Perforating

High precision processing robot makes it possible, with a single robot, to make various processing that used to be made in separate processes using presses, etc.

High precision processing robot makes it possible, with a single robot, to make various processing that used to be made in separate processes using presses, etc.

The picture shows a sample being perforated with a high-speed robotic system.

Video, zoomed-in (WMV: 10.2MB)

Video, system arrangement (WMV : 14.7MB)

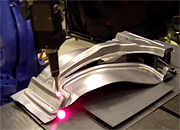

Robotic Trimming

High precision processing robot makes it possible, with a single robot, to make multiple trimming operations that used to be made in separate processes.

High precision processing robot makes it possible, with a single robot, to make multiple trimming operations that used to be made in separate processes.

The picture shows a sample being trimmed with a robot.

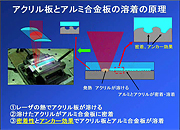

Joining Resins with Metals

Characteristics of laser make it possible to join various materials that used to be considered impossible to join. This is a new technology expected to be put to practical use in various industries from now on.

Characteristics of laser make it possible to join various materials that used to be considered impossible to join. This is a new technology expected to be put to practical use in various industries from now on.

The picture explains the principle of welding of acrylic plate and aluminum alloy plate.

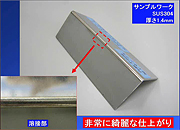

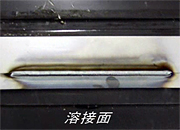

Spatter-less Corner Joint Welding

Smooth weld bead surface finish could be achieved by selecting the optimum processing conditions. This eliminates the need for a surface grinding process, which leads to lower investment costs.

Smooth weld bead surface finish could be achieved by selecting the optimum processing conditions. This eliminates the need for a surface grinding process, which leads to lower investment costs.

The picture shows surface finish after welding.

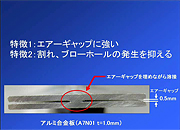

Laser-MIG Hybrid Welding

For welding materials having a gap in between, or hard-to-weld materials of high weld cracking sensitivity, laser-MIG hybrid welding is beneficial as it can weld the materials by filling the gap taking the advantage of deep weld penetration of MIG, and is applicable to weld hard-to-weld materials.

For welding materials having a gap in between, or hard-to-weld materials of high weld cracking sensitivity, laser-MIG hybrid welding is beneficial as it can weld the materials by filling the gap taking the advantage of deep weld penetration of MIG, and is applicable to weld hard-to-weld materials.

The picture shows the aluminum alloy plates welded with air gap of 0.5 mm in between.

5-axis Laser Machine (manufactured by Trumpf)

This is a super dynamic 5-axis laser machine boasting a feed speed of up to 100 m/min. This is an intuitive and user-friendly system and can be incorporated with CAM system promising smooth processing. A disk laser oscillator that matches the specification can be selected.

This is a super dynamic 5-axis laser machine boasting a feed speed of up to 100 m/min. This is an intuitive and user-friendly system and can be incorporated with CAM system promising smooth processing. A disk laser oscillator that matches the specification can be selected.

The picture is an overall view of TruLaser Cell7040 manufactured by Trumpf.

3-dimensional Laser Processing Machine

(manufactured by Mitsubishi Electric Corporation)

This system improves the operability of the teaching box that specifies the sequence in three-dimensional processing, whereby the total of setup time and processing time can be shortened, resulting in the productivity improvement. Application of this machine can be expanded to wide range of processing including welding and cutting of heavy plates with CO2 laser.

This system improves the operability of the teaching box that specifies the sequence in three-dimensional processing, whereby the total of setup time and processing time can be shortened, resulting in the productivity improvement. Application of this machine can be expanded to wide range of processing including welding and cutting of heavy plates with CO2 laser.

The picture is an overall view of VZ20-40CF-R manufactured by Mitsubishi Electric Corporation.

Arc Welding

Tracking System

This system detects the weld line with a laser sensor, whereby semi-automatic arc welding can be performed. If the pattern of the weld line is similar to from one to another, misalignment of work is tolerated to some extent.

This system detects the weld line with a laser sensor, whereby semi-automatic arc welding can be performed. If the pattern of the weld line is similar to from one to another, misalignment of work is tolerated to some extent.

The picture shows a welding demonstration where a Servo-Robot laser sensor is detecting the weld line.

Multilayer Welding Robots

This system can automatically operate Multilayer Welding by setting a starting and a finishing point. This system can conduct wide bead welding by adjusting weaving movement.

This system can automatically operate Multilayer Welding by setting a starting and a finishing point. This system can conduct wide bead welding by adjusting weaving movement.

The picture shows our DERA-ROBO.

Low Spatter Arc Welding

CMT (Cold Metal Transfer) welding is a new type of short circuiting arc welding that can minimize spattering less than pulse welding can, by repeating very high-speed feeding and retracting of welding wire during welding. This can minimize heat generation during welding, thus is applicable to the welding of ultra light gage sheets.

CMT (Cold Metal Transfer) welding is a new type of short circuiting arc welding that can minimize spattering less than pulse welding can, by repeating very high-speed feeding and retracting of welding wire during welding. This can minimize heat generation during welding, thus is applicable to the welding of ultra light gage sheets.

The picture shows a work sample welded with a system composed of Yaskawa robot and CMT.

Roll-hemming System

Robotic Roll-hemming System

Hemming is a kind of forming to bend the sheet metal edges. Formerly popular hemming method used to be press-hemming that requires various kinds of dies depending on the work shape and die-changeover. Nadex now proposes roll-hemming system where hemming rollers are mounted to the robot arm. The system can flexibly perform hemming depending on the work shape.

Hemming is a kind of forming to bend the sheet metal edges. Formerly popular hemming method used to be press-hemming that requires various kinds of dies depending on the work shape and die-changeover. Nadex now proposes roll-hemming system where hemming rollers are mounted to the robot arm. The system can flexibly perform hemming depending on the work shape.

The picture shows robotic roll-hemming in operation.

Weld Quality Inspection System

Robotic Inspection System

This is a system that can monitor the weld bead after welding in real time with a laser sensor, thus precisely inspect the quality of the weld. Since the setting of weld quality inspection items can be changed according to customer’s specifications, it is possible to control the process according to the production volume.

This is a system that can monitor the weld bead after welding in real time with a laser sensor, thus precisely inspect the quality of the weld. Since the setting of weld quality inspection items can be changed according to customer’s specifications, it is possible to control the process according to the production volume.

The picture shows an application example where Servo-Robot sensor is used.

![NADEX[株式会社ナ・デックス]](https://www.nadex.co.jp/wp-content/uploads/2020/03/logo.png)